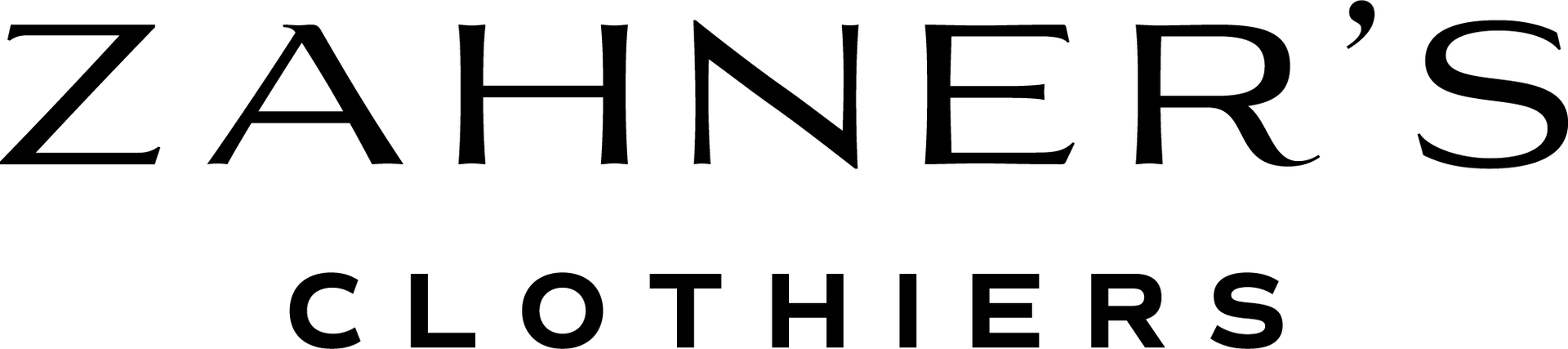

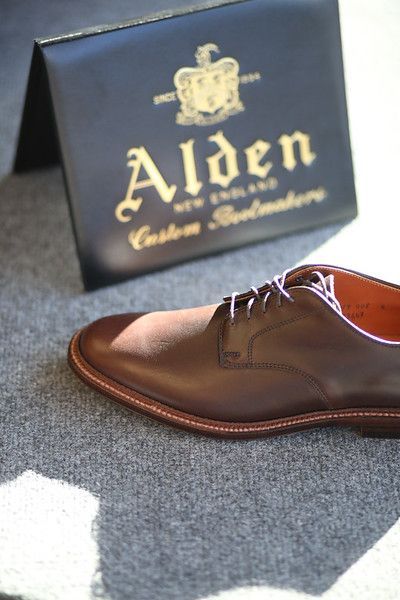

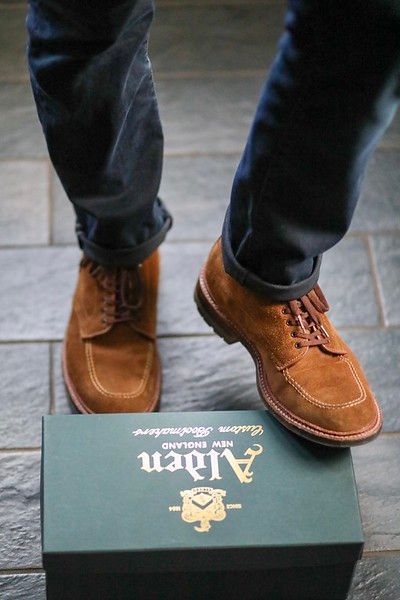

ALDEN SHOES

Founded in 1884, by Charles Alden, the Alden Shoe Company has been making men's shoes and custom boots for almost 140 years.

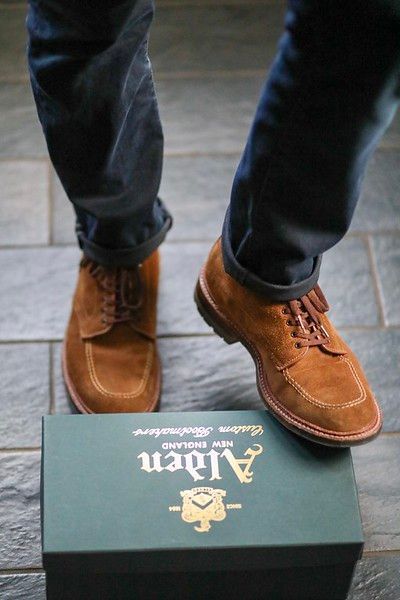

After many years of economic and fashion swings Alden is now the only original New England shoe and bootmaker remaining of the hundreds who began so long ago. Still a family owned business, and still carrying forward a tradition of genuine-welted shoemaking that is exceptional in every way.

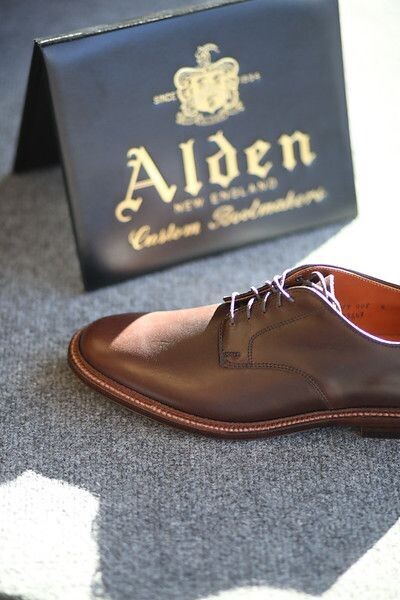

A customer and employee favorite, Alden shoes are hand-crafted, and built to last using only the finest leathers and materials. Every single style is resoleable, and will take care of your feet for many years to come.

Every Alden shoe and boot is, and has been made in Middleboro Massachusetts since 1884.